NASA Is Testing 3D-Printed Moon Infrastructure In Orbit

This isn’t about printing souvenirs in space. It’s about figuring out how humans might build, repair, and survive off-world.

The future of lunar construction just moved off Earth

For decades, building on the Moon sounded like sci-fi.

Now, it’s being tested above our heads.

A U.S. space company is preparing to demonstrate in-space additive manufacturing designed for the lunar surface not in a lab, but aboard the International Space Station. And it’s happening as NASA’s Artemis program pushes closer to long-term Moon missions.

What’s actually happening on the ISS

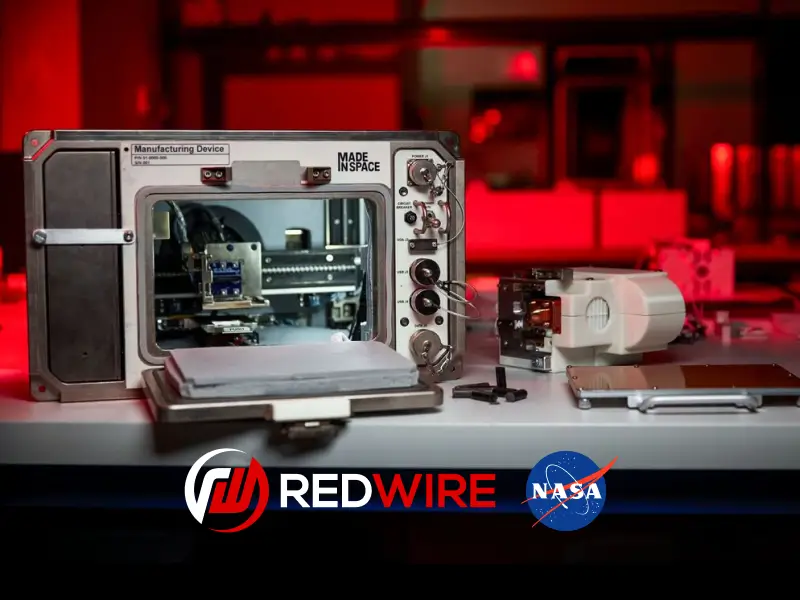

Redwire, a Florida-based space infrastructure company, announced it will demonstrate a new in-space manufacturing capability designed to replicate conditions needed for building structures on the Moon.

Instead of shipping everything from Earth, the idea is simple and radical:

Use local lunar material to build what you need, where you need it.

The ISS test will evaluate how additive manufacturing systems behave in microgravity using materials relevant to lunar surface construction, helping engineers understand what works and what doesn’t before Artemis astronauts ever land.

Here’s What You Need to Know

Here’s what Redwire is testing and why it matters:

- In-space 3D manufacturing designed for lunar use

- Systems meant to work with Moon-relevant materials, not Earth-only supplies

- A technology path that supports NASA’s Artemis missions

- A focus on infrastructure, not experiments or novelty prints

In short: this is about printing the future Moon base, not prototypes.

Why this is a big deal for space exploration

Launching materials from Earth is brutally expensive.

Every kilogram costs money, fuel, and time.

If future missions can manufacture tools, parts, or structures using lunar resources, everything changes:

- Fewer launches needed

- Longer missions become realistic

- Permanent lunar presence becomes feasible

This is the shift from exploration to settlement.

NASA has made it clear: Artemis isn’t a flag-and-footprints mission. It’s about building sustainable operations on the Moon and eventually Mars.

Redwire’s test is part of that foundation.

A larger trend is forming in space tech

This isn’t happening in isolation.

Across the space industry, companies are racing to build commercial space infrastructure, including:

- On-orbit manufacturing

- Autonomous construction systems

- Lunar rover technology for material handling

- Surface power, habitats, and logistics

The Moon is becoming a testbed for deep-space civilization, and manufacturing is one of the hardest problems to solve.

If you can build off-world, you don’t just visit space you stay.

Who benefits from this technology

- NASA: Lower costs, more resilient missions

- Commercial partners: New markets beyond Earth orbit

- Future astronauts: Safer, more flexible surface operations

- Space economy: Infrastructure unlocks everything else

This is how space stops being an event and becomes an industry.

What comes next

The ISS demonstration will help determine how viable these systems are before they’re deployed on the Moon itself.

If successful, it pushes lunar construction from theory into operational reality just in time for the next phase of Artemis.

The Moon isn’t just a destination anymore.

It’s becoming a job site.