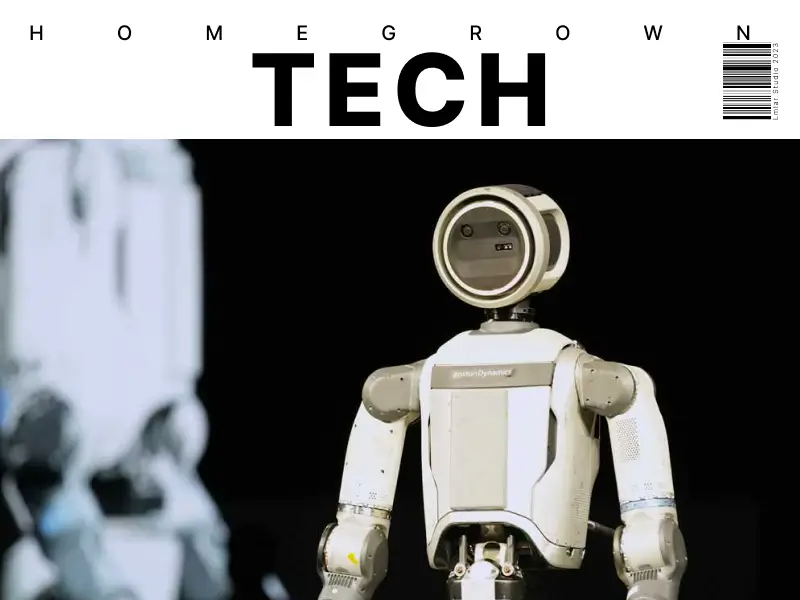

Atlas robot enters Hyundai factories in production shift

Atlas, Boston Dynamics’ humanoid robot, is moving into Hyundai factories—signaling a major shift in AI-powered manufacturing and automation.

Atlas, the humanoid robot developed by Boston Dynamics, is no longer just a research spectacle. Within its first steps into real-world deployment, Atlas is being prepared for use inside Hyundai manufacturing facilities, marking a turning point where advanced robotics and AI leave controlled demos and enter industrial production. This move reflects a broader shift in how robots are expected to operate alongside human workers at scale.

What Atlas is and what changed

Atlas is Boston Dynamics’ most advanced humanoid robot, redesigned to handle real manufacturing tasks rather than experimental demonstrations.

Why Hyundai is deploying humanoid robots

Hyundai’s investment signals a push toward flexible automation where robots can adapt to varied tasks, not just repetitive assembly-line work.

Key production capabilities of Atlas

The robot is built for strength, balance, and AI-driven movement, enabling it to lift, carry, and navigate complex factory environments.

How this compares to traditional factory robots

Unlike fixed industrial arms, Atlas can move freely, making it useful in dynamic spaces where human workers typically operate.

What this means for the future of manufacturing

Humanoid robots could redefine factory labor, blending AI, robotics, and human oversight in ways not previously practical.

Tags: robotics, humanoid-robots, artificial-intelligence, manufacturing, automation, boston-dynamics